THE ALU STONE SYSTEM

Do you install kitchens with stone partition ? then here is the tremendous solution for you to discover, the all new "Alu-Stone" system. Alu-stone system is the set of 4

aluminium sections, which can be screwed directly to the stone partition only once and preventing onself from screwing each and every hardware like Hings and Channels to

stone. Rather Hings and Channels can be installed by way of creating a bond between zinc inserted in the Aluminium section with single and double holes for channel and

things respectively and hardware.

GRADE

6063 ALUMINUM ALLOY

Base raw material used to manufacture the system is aluminum alloy of 6063 grade, it is a medium

strength alloy specially referred as an architectural alloy. Said grade is normally used in intricate

extrusion and has the architectural applications including Window frames, partition system,

furniture profiles and shop fittings.

FAST

Result of extreme research and craftsmanship makes it easy and fast to install, accelerating the

schedule. It can fast reconfigured, shifted and re-ercted. Panels and glass can be removed

independently without concern for sequence. More of the interlocking method of installing unlike

to permeative screwing system.

FLEXIBLE

A proven and practical approach to space division which can integrate with both existing building

infrastructure and furniture system. Emense possibility to rapidly reconfigure without demolition.

Systems flexibility responds with ease to meet the changing needs of once organization

Kitchen With Vertical Marble / Kadappa Partion

Comparison Between Conventional & Alu - Stone System

The Conventional System

Alu-stone System

Fixing Hinge

You have to drill 4 holes

To fix 2 hinge.

No drilling required.

Fixing Channels

You have to drill at least 12 holes to fix 3 baskets.

No drilling required.

Framing

You have to make frame work of aluminum or word.

No frame work is required. You have to fix only four pcs of section drilling 8 holes and fixing eith cabinet connector so no word grip is required.

Distance Between Two Channels

Is never accurate to make it exact parallel you have to adjust it with various size of washers.

Only have to aligned 4 alu-stone section to make one cavity with equal distance in between.

SUSTAINABLE

We at msquare understand the sustainablity and so the system has been developed. Practically

eliminates construction waste and mess. Expanded capacity for utility and technical infrastructure.

System can be rapidly reconfigured without demolition. Further, it is 99% reusable and 100%

recyclable.

ECONOMY

All the above qualities make this system economical, ass it provides the best solution with great

flexibility and sustain ability in a faster manner. Same system can incorporate wide range of insert

options to suit the budgets, can assume the customer or millwork appearance System can be used

as storefront.

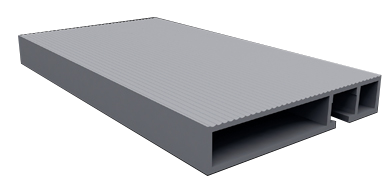

Profile & Hardware

SHARE